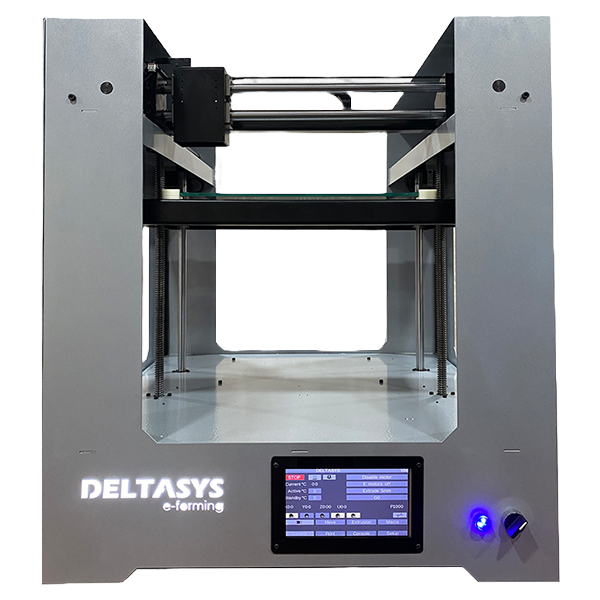

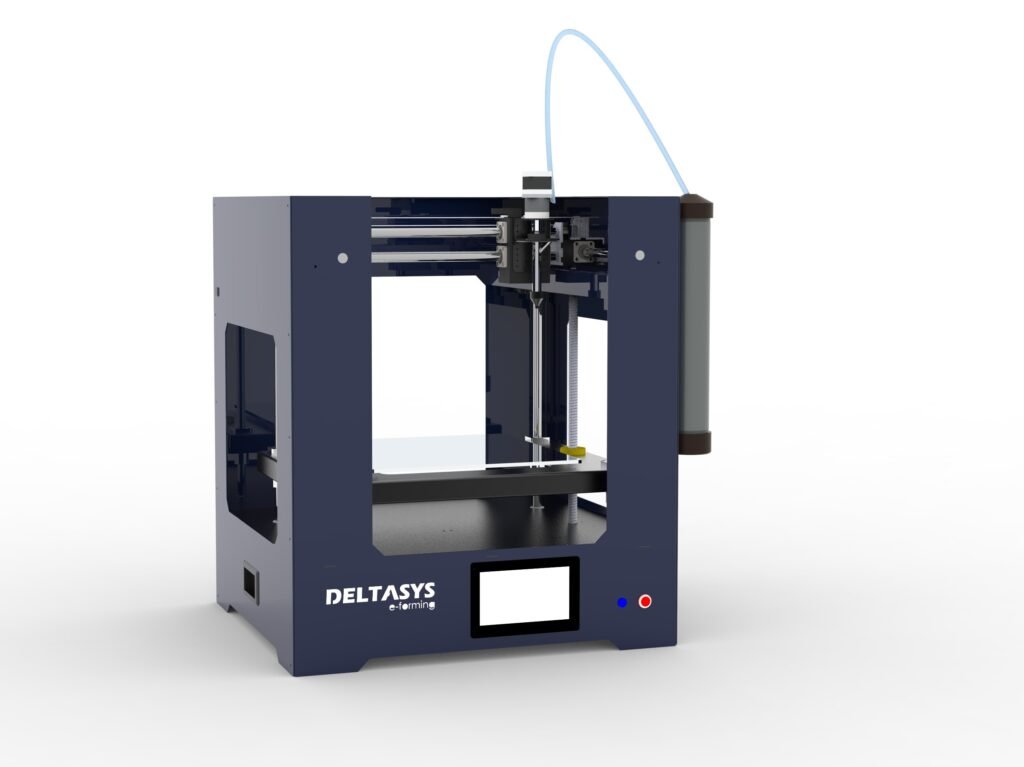

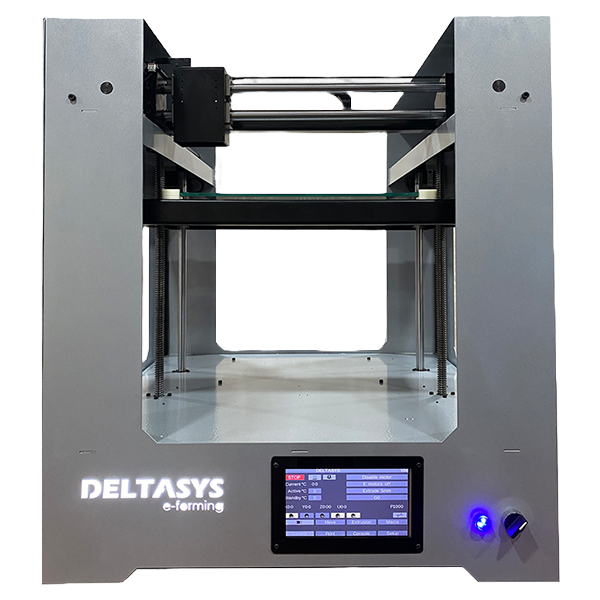

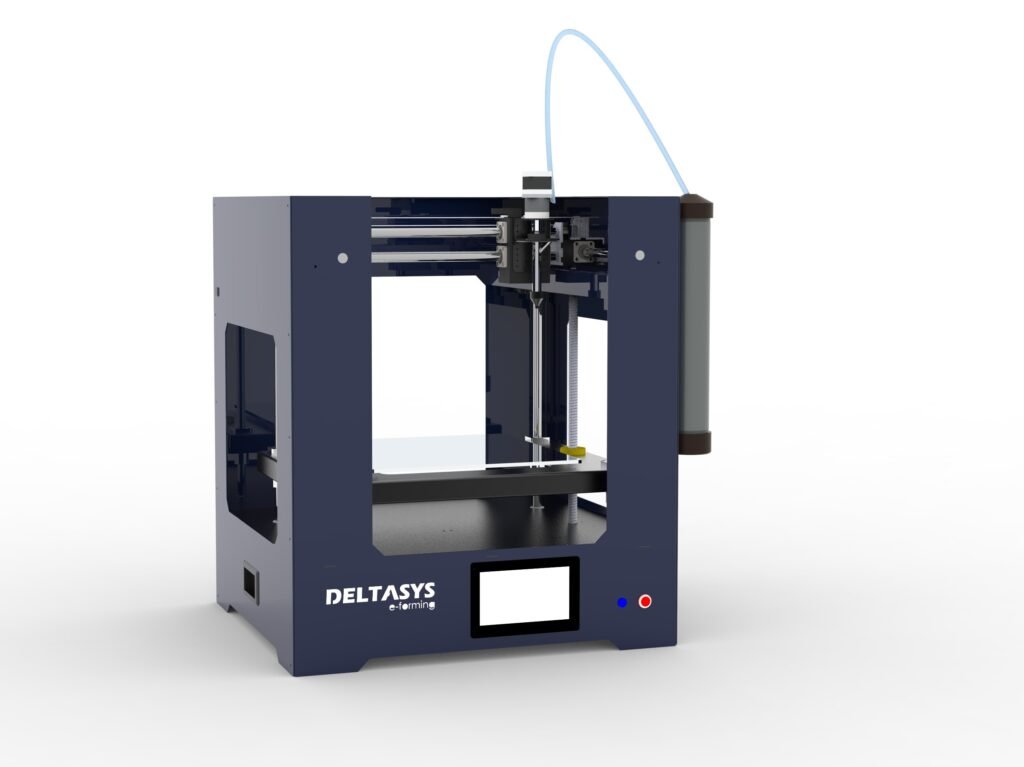

Deltasys E-Forming Clay 3D Printer uses the extrusion head which extrudes porcelein clay, terra cotta clay, ceramic clay and all types of other clay. Also it extrudes all kinds of paste materials such as cement paste and can be modified to extrude chocolates or foods.

Clay 3D Printer

Clay 3D Printer

Overview

DELTASYS EFORMING CLAY 3D PRINTER is a specialized machine designed for creating objects using clay or other ceramic materials. Utilizing additive manufacturing, it extrudes layers of soft clay through a nozzle to build complex shapes and intricate designs. These printers are popular in art, pottery, and architectural applications, enabling artists and designers to experiment with innovative forms and textures. Clay 3D printing offers precision, repeatability, and the ability to produce customized designs that are difficult to achieve manually.

3D PRINTER

CLAY 3D PRINTER

Clay 3D Printers are widely used in artistic and functional applications, such as pottery, sculpture , and architectural components. They offer unmatched precision, repeatability, and customization, enabling designers and artists to explore innovative forms and textures. Clay 3D printer is available in different sizes as per customer specifications.

3D Printer

For complete specifications and detailed product description of our Clay 3D Printer—Please Contact Us

DELTASYS E-FORMING invents, designs and builds specific high tech and high production 3D Printing Machines & CNC Machining Centres.

- +91 8050583644

- info@3deltasys.com

- Plot No-30A, RS No-703/L, behind GIT College, beside Omkar Roadways, Udyambag Industrial Area, Udyambag, Belagavi, Karnataka 590008-INDIA

Concrete 3D Printer

- Table Top Small R&D Concrete 3D Printer

- E-Builder Lab Scale Concrete 3D Printer

- Large Scale Concrete 3D Printer

All Rights Reserved by Deltasys E-Forming © 2024